A large step for open source 3D Printers.

Lowering the boundaries to access big prints for everyone.

Compact and interoperable design.

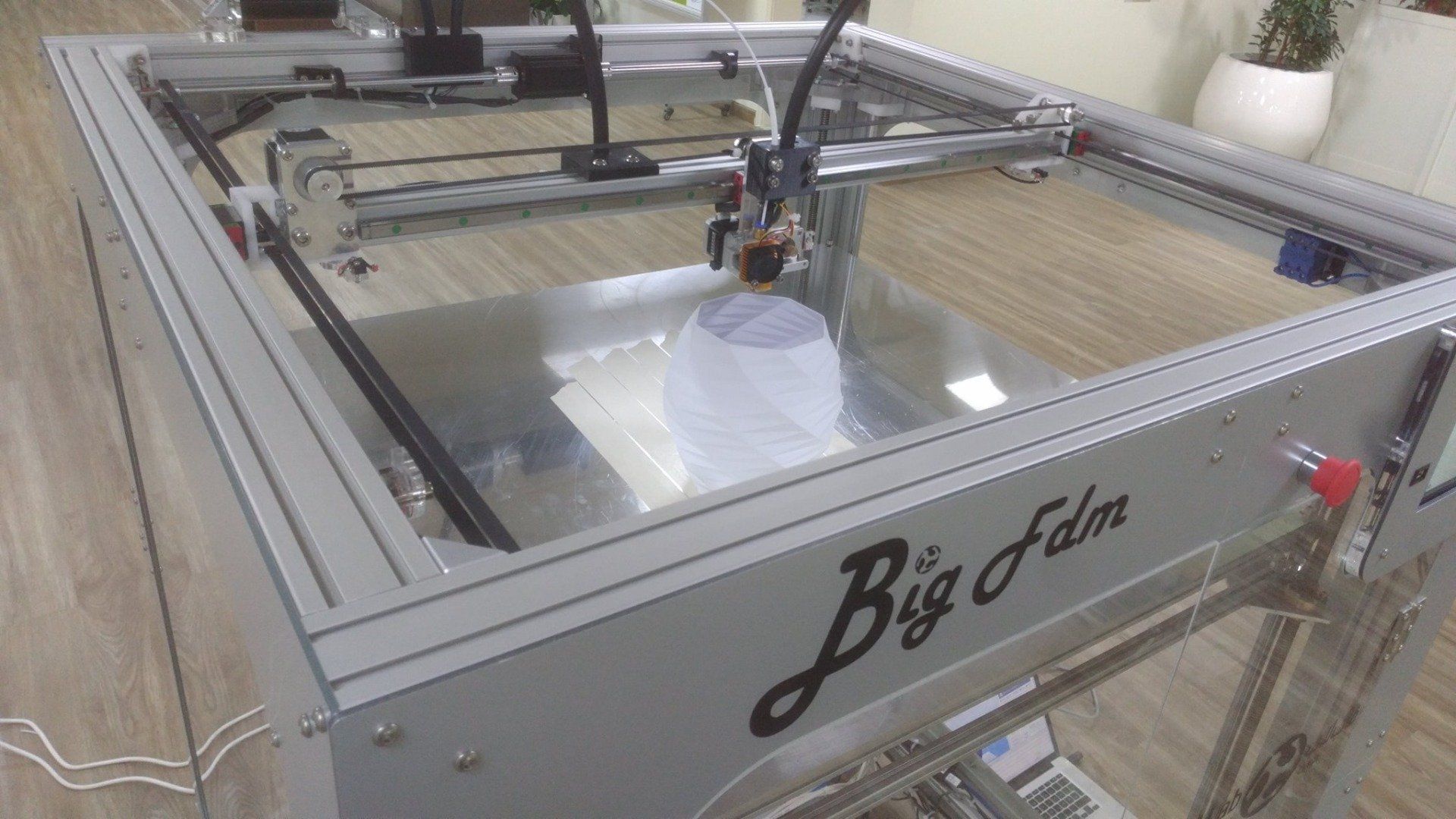

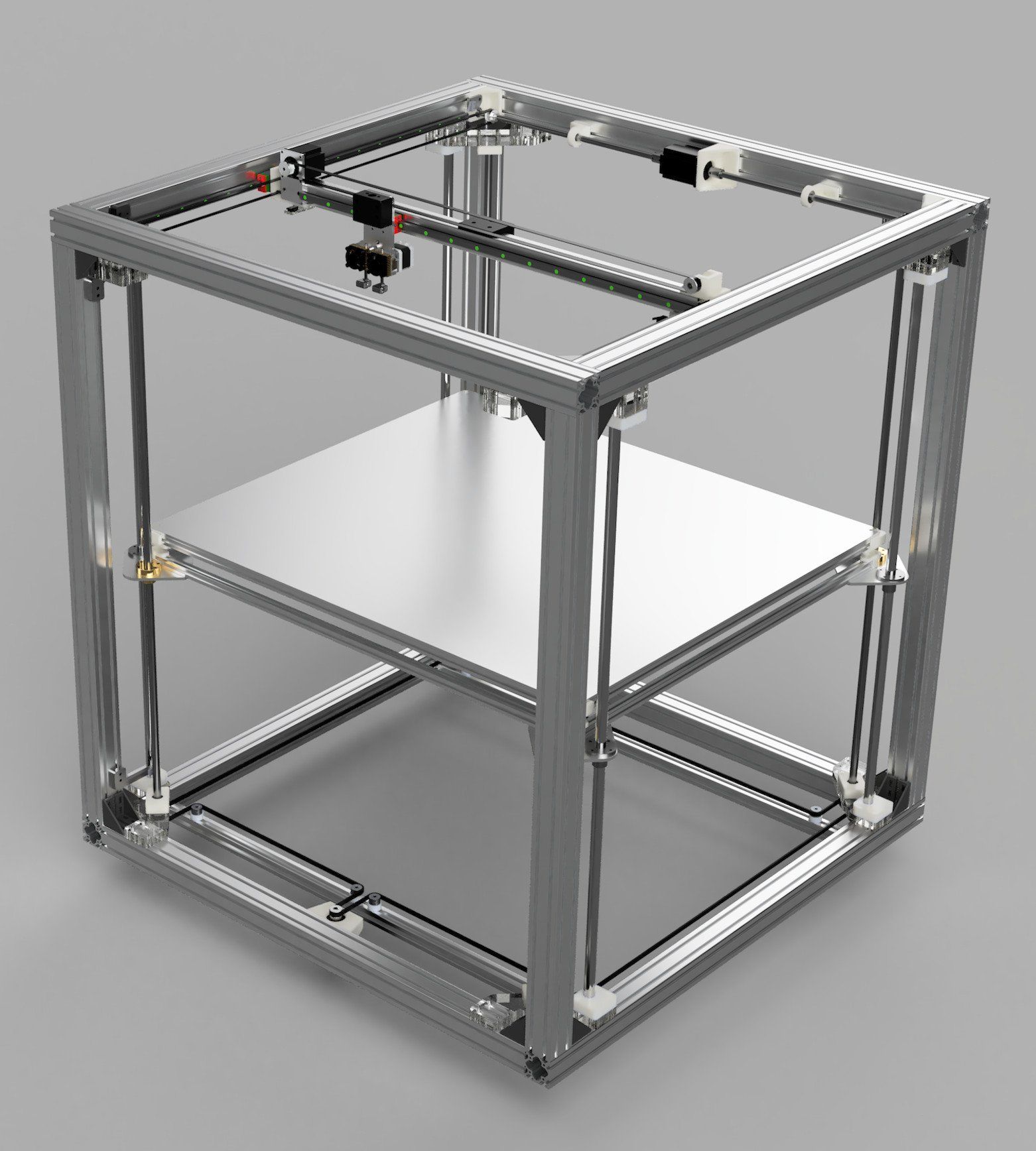

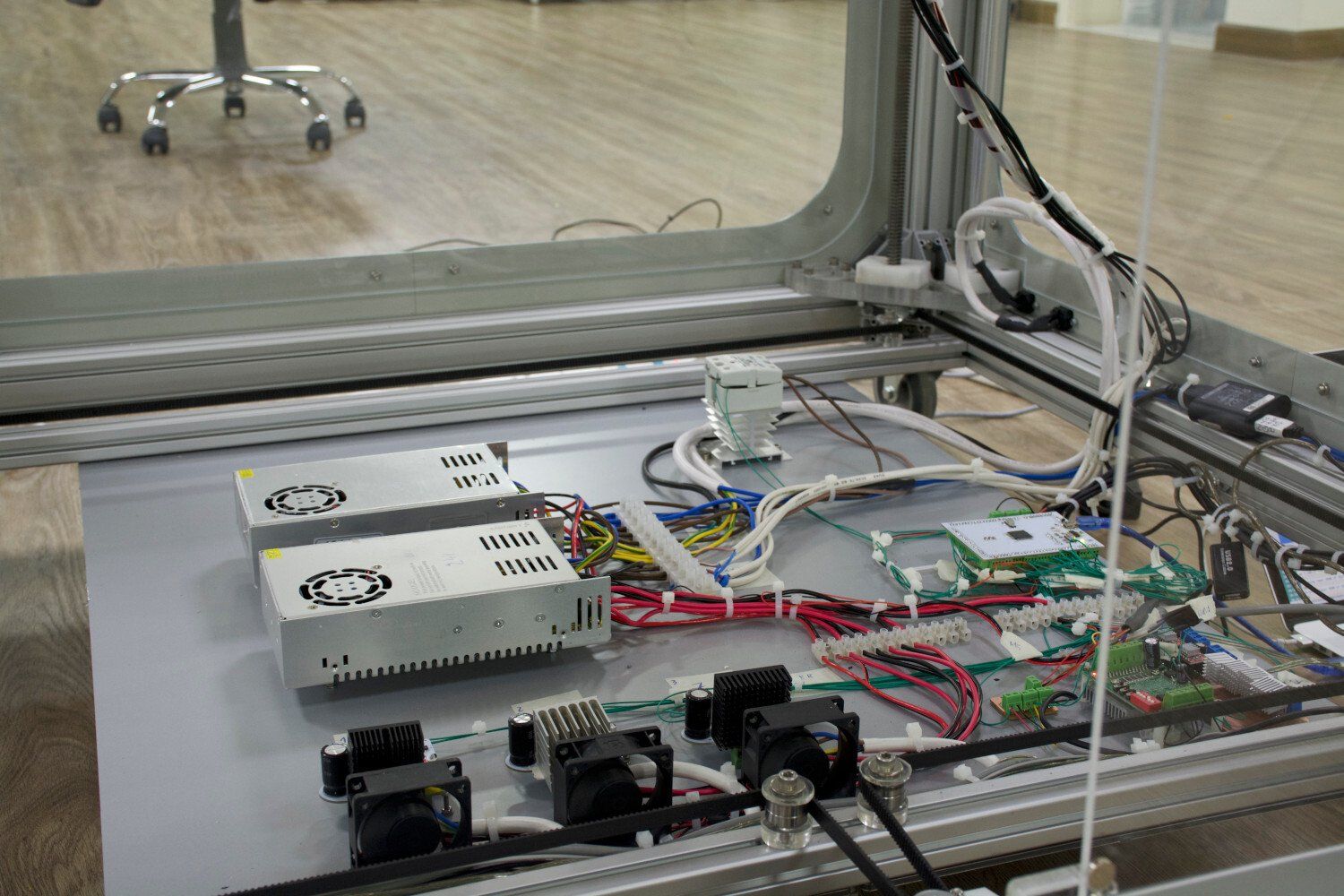

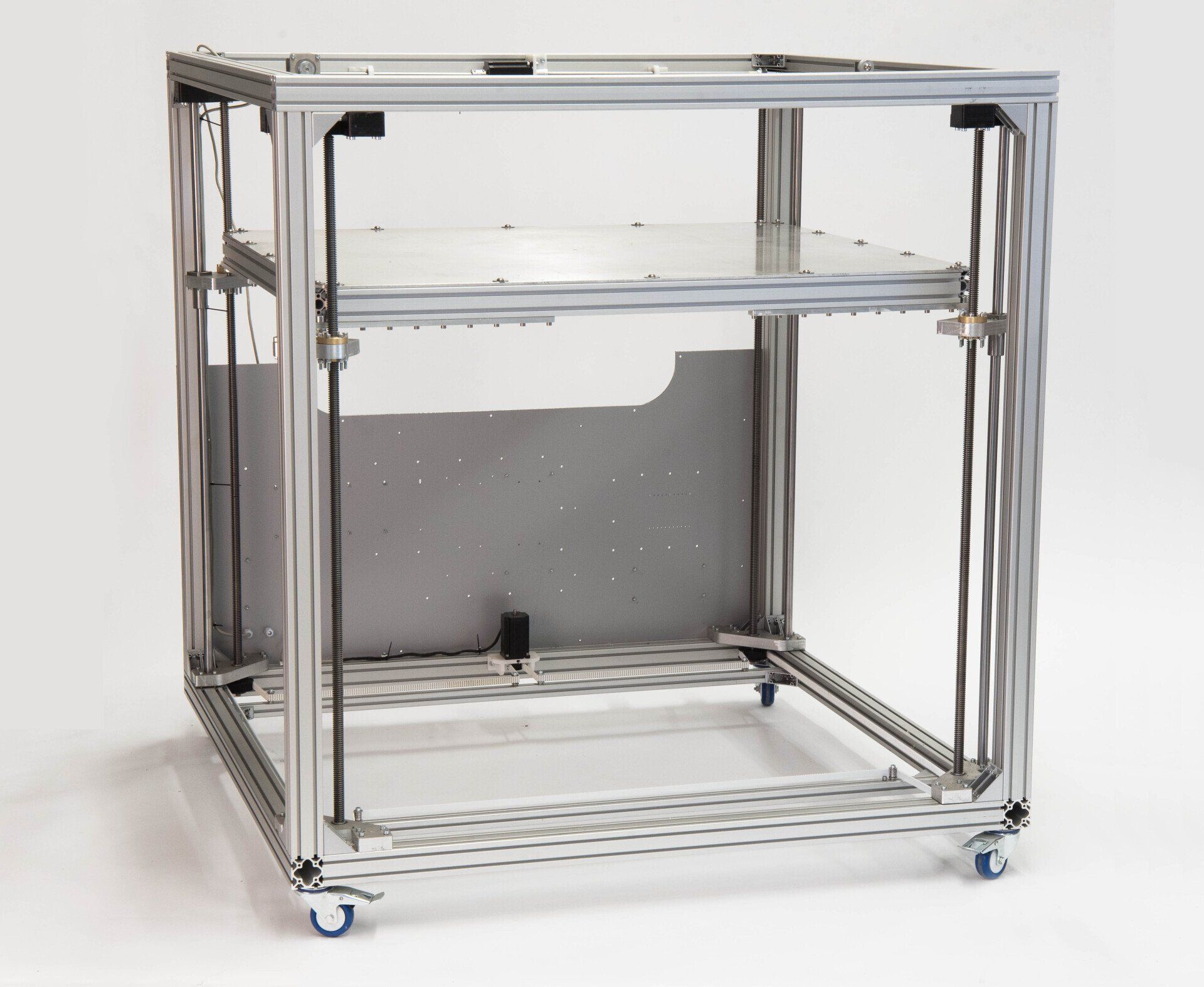

The design BigFDM has been influenced by several initial considerations, as an outcome of the past machine building experiences. Core of BigFDM is the frame and its dimensions, which have been designed as first element. Everything else has been then adapted to fit inside the frame, minimizing as much as possible the distance with the internal structures, in order to maximize the printing area.

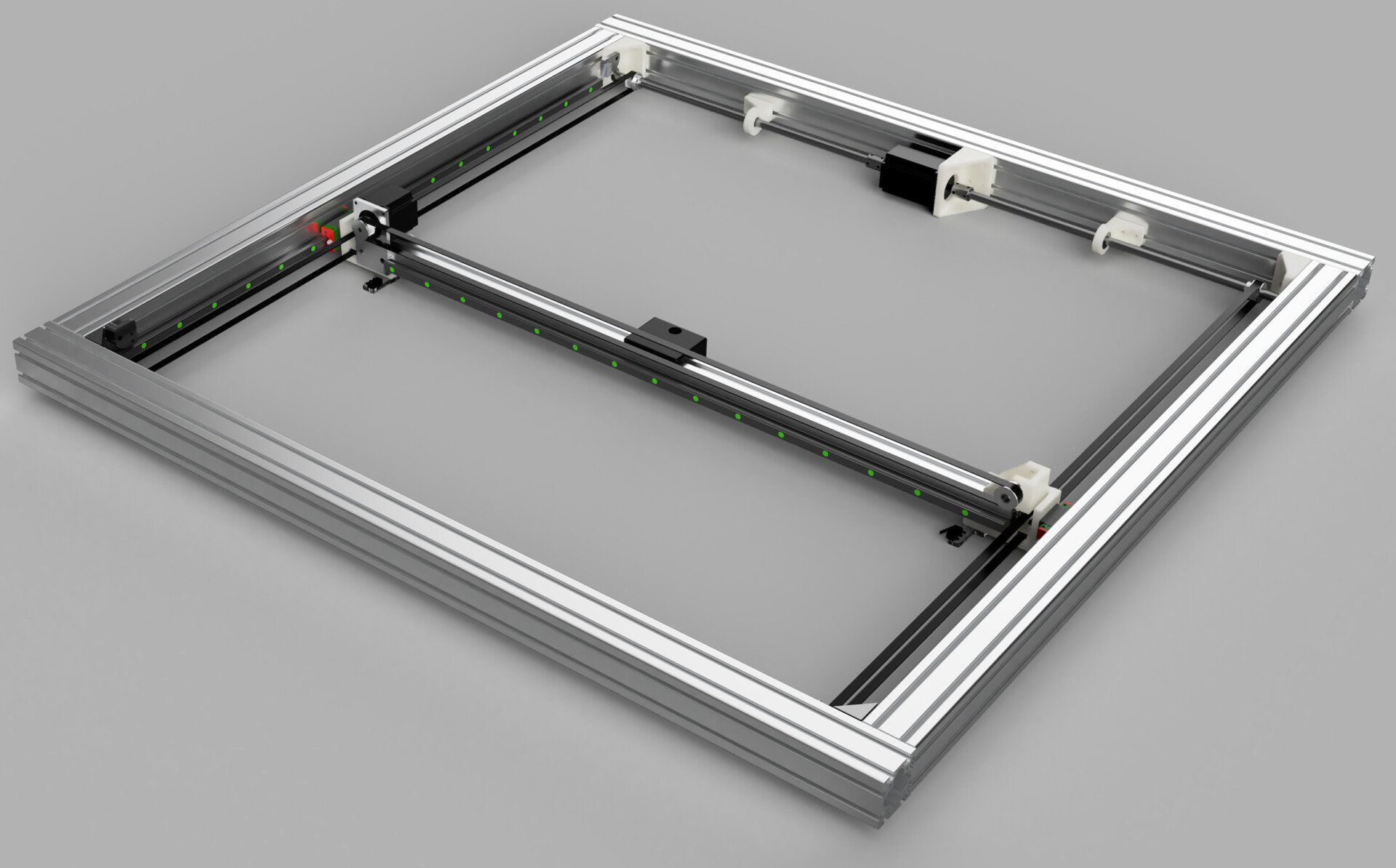

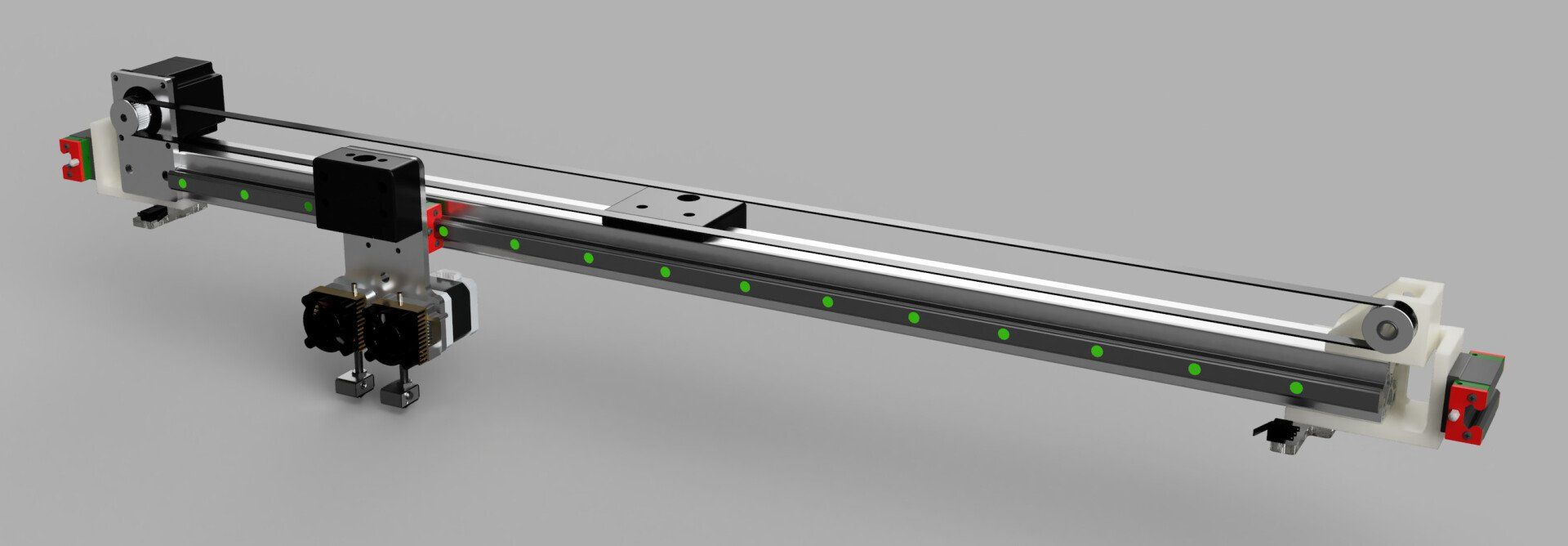

The X and Y axis integrate all their components inside the top square of the frame. This configuration implements the interoperability of the stages, with the top frame that can be completely detached from the machine, and virtually, plugged into a different machine having similar frame shape (eg a laser cutter).

Similar interoperability has also been recursively kept for the Y axis, which can be modified/removed without changing the X axis.

Download it globally, produce it locally

BigFDM was first built in Dubai, with the help of Hashim Al Sakkaf, Fab Academy Instructor of Fab Lab UAE.

In the following link the documentation of the machine, and its open source certification.

- BigFDM Github Repository: https://github.com/fab-machines/BigFDM

- BigFDM OSHWA Certification: https://certification.oshwa.org/de000013.html

BigFDM specifications:

| Printing Area | 800 x 800 x 900mm |

|---|---|

| Extruder | Dual extruder with interchangeable nozzles |

| Filament | 2.85mm |

| Mechanics | Linear Rails, GT2 and HTD3 Belts |

| Motors | Stepper Nema 23 and 24 |

| Bed | Heated Aluminum, 4 x 750W heaters |

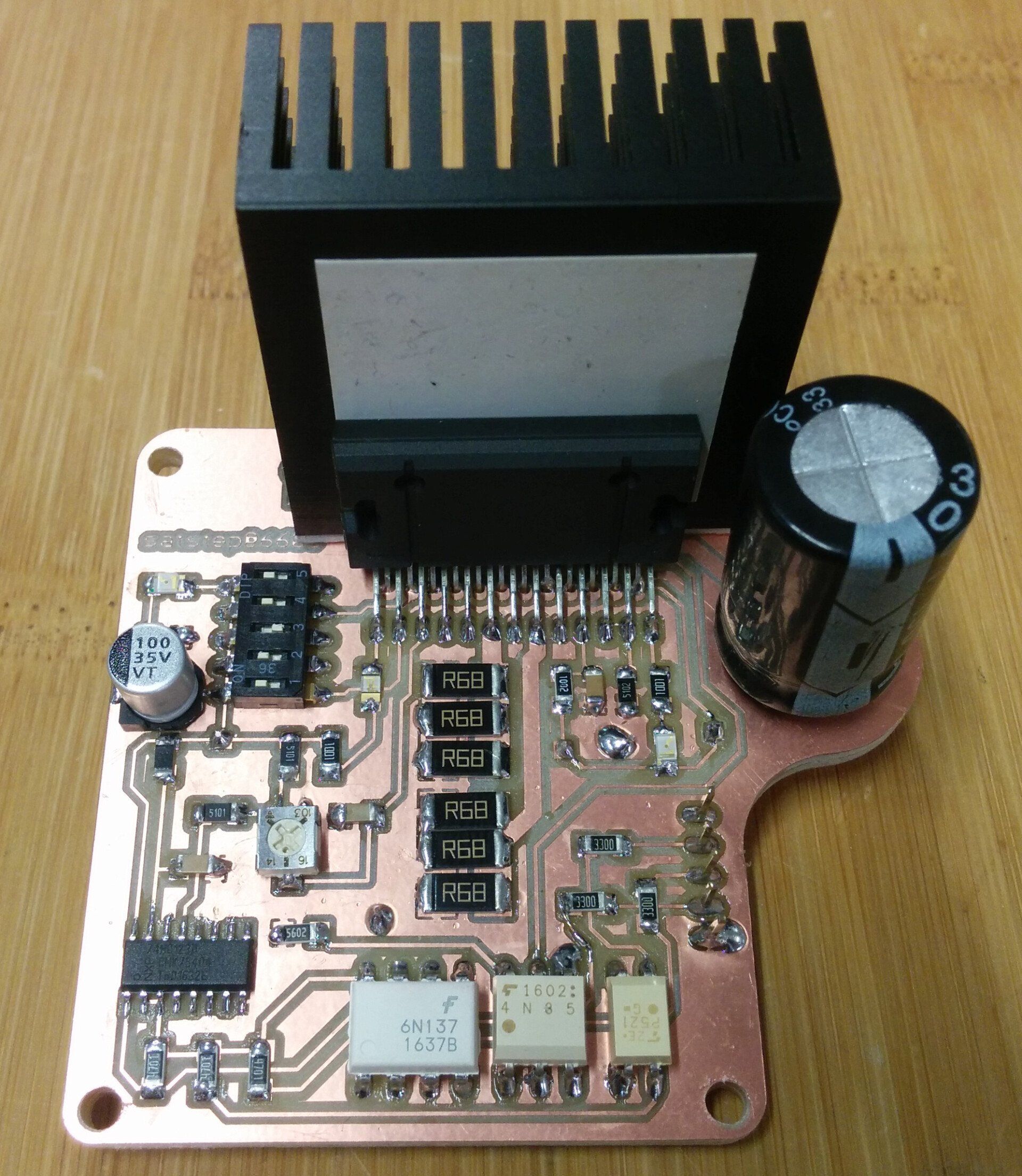

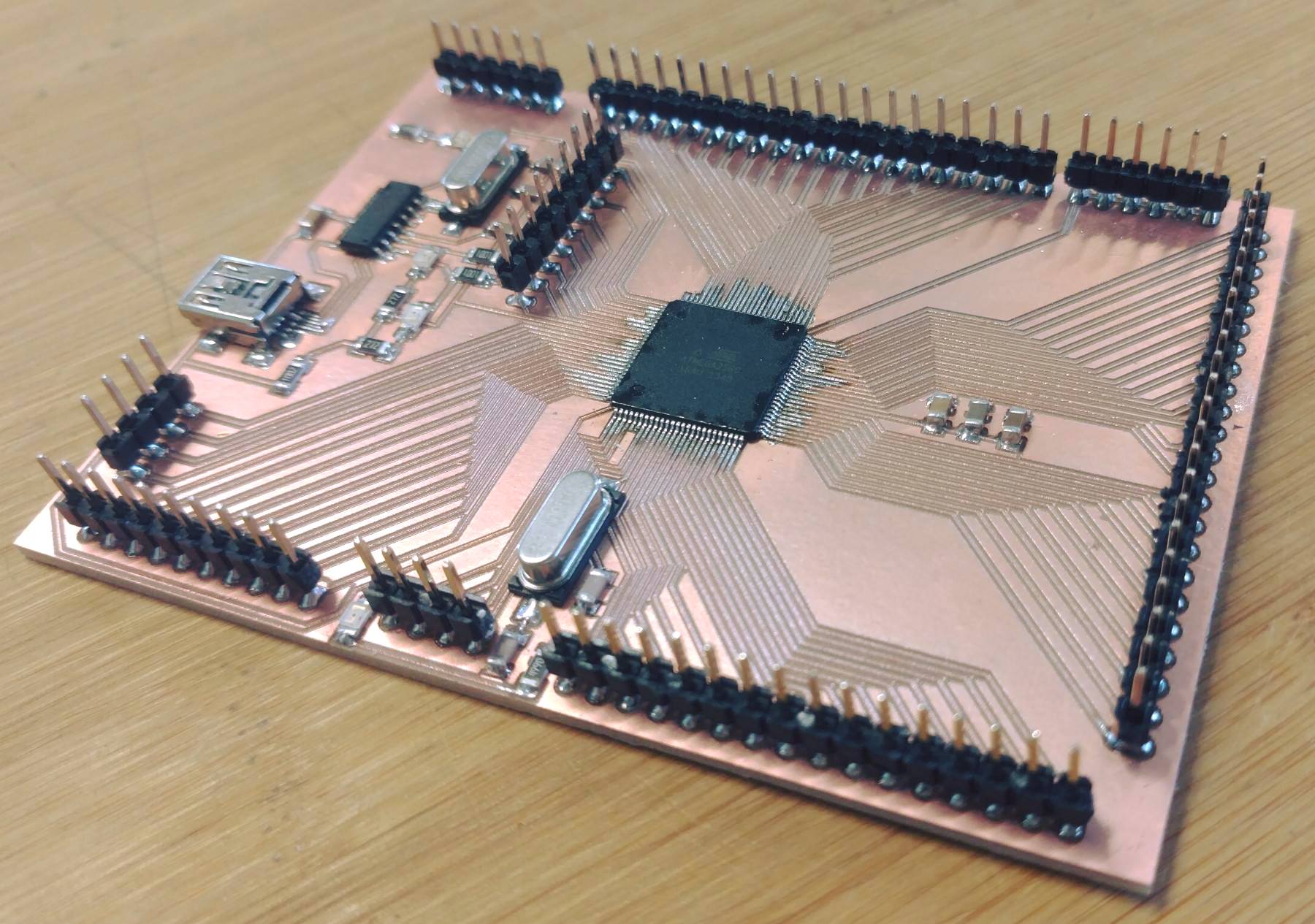

| Electronics | Satshakit and Satstep6600 locally fabricated boards |

| Frame | 60 x 60mm Aluminum profiles |

| Interface | Integrated Tabled for machine control |

| Housing | Aluminum Composite 3mm and 4mm Acrylic |

| Power | 220V, 3000W max |

A new Open Source flagship : BigFDM ONE

Being under development, and designed on top the experience made with BigFDM, BigFDM One represents an overall improvement of the large scale 3D printer. Increasing the size to 1000x1000x1000mm, using inductive sensors and with a reinforced building platform, BigFDM One wants to set higher standard for the large scale open source 3D printers.