Open Lab Starter Kit

An open source set of machines for Fab Labs and Open Labs

What is OLSK?

Creating means to create.

Starting a digital fabrication workshop requires a set of machinery, which are often imported and unaffordable. The Open Lab Starter Kit is a project in cooperation with Fab City Hamburg which aims to create a repository of open source machines to be replicable locally and with lower costs.

OLSK Goals

Global knowledge. Accessible local production.

Develop Open Source Digital Fabrication Machines

Document the reproduction process

Transfer the knowledge behind the machines

Create fully Open Source Fab Labs (Open Labs)

Fill the gap between commercial and Open Source machines

Lower the barriers in accessing digital fabrication technologies

Include and enable anyone in the process

Boost the Fab Cities local production and circular economy

OLSK Machines

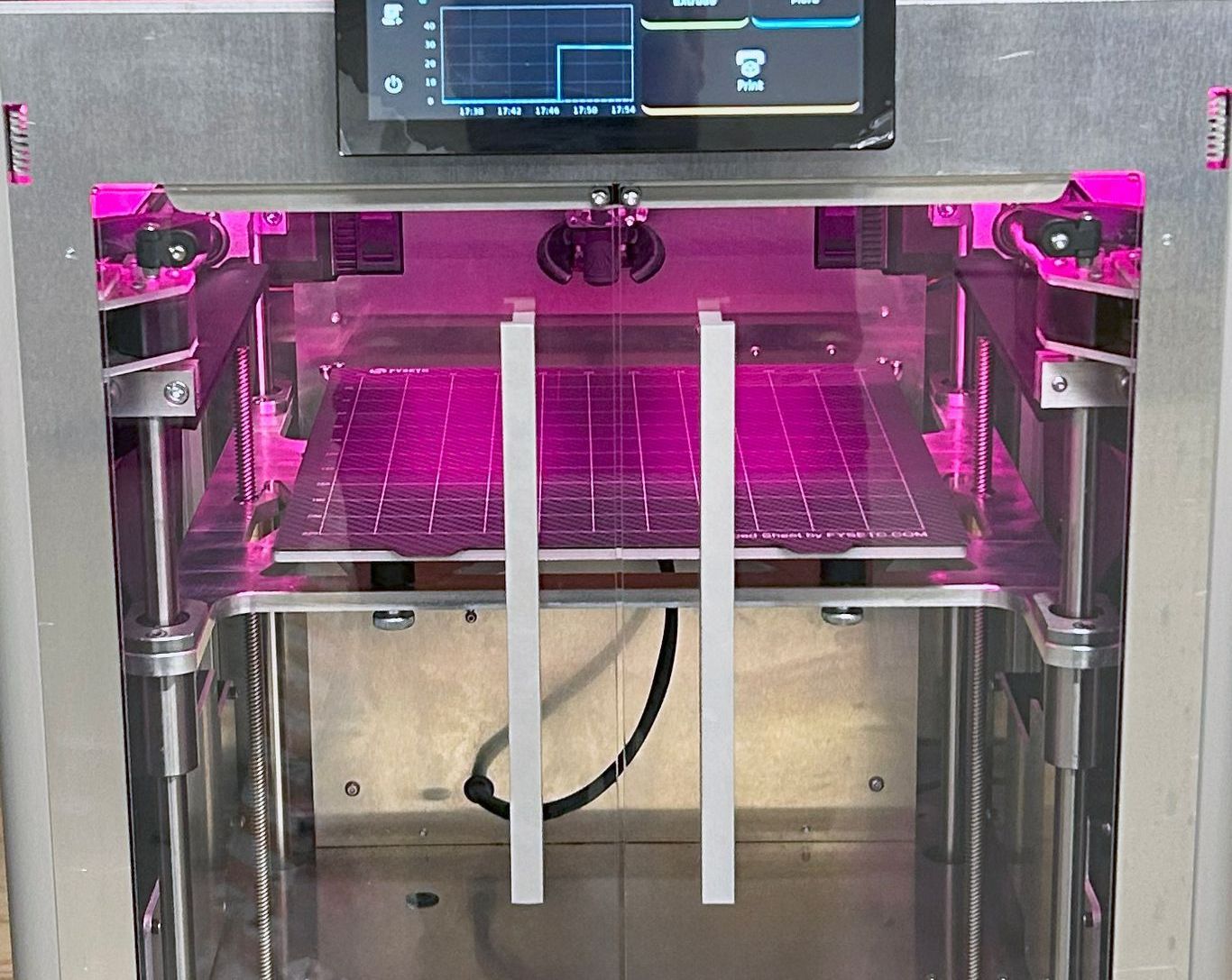

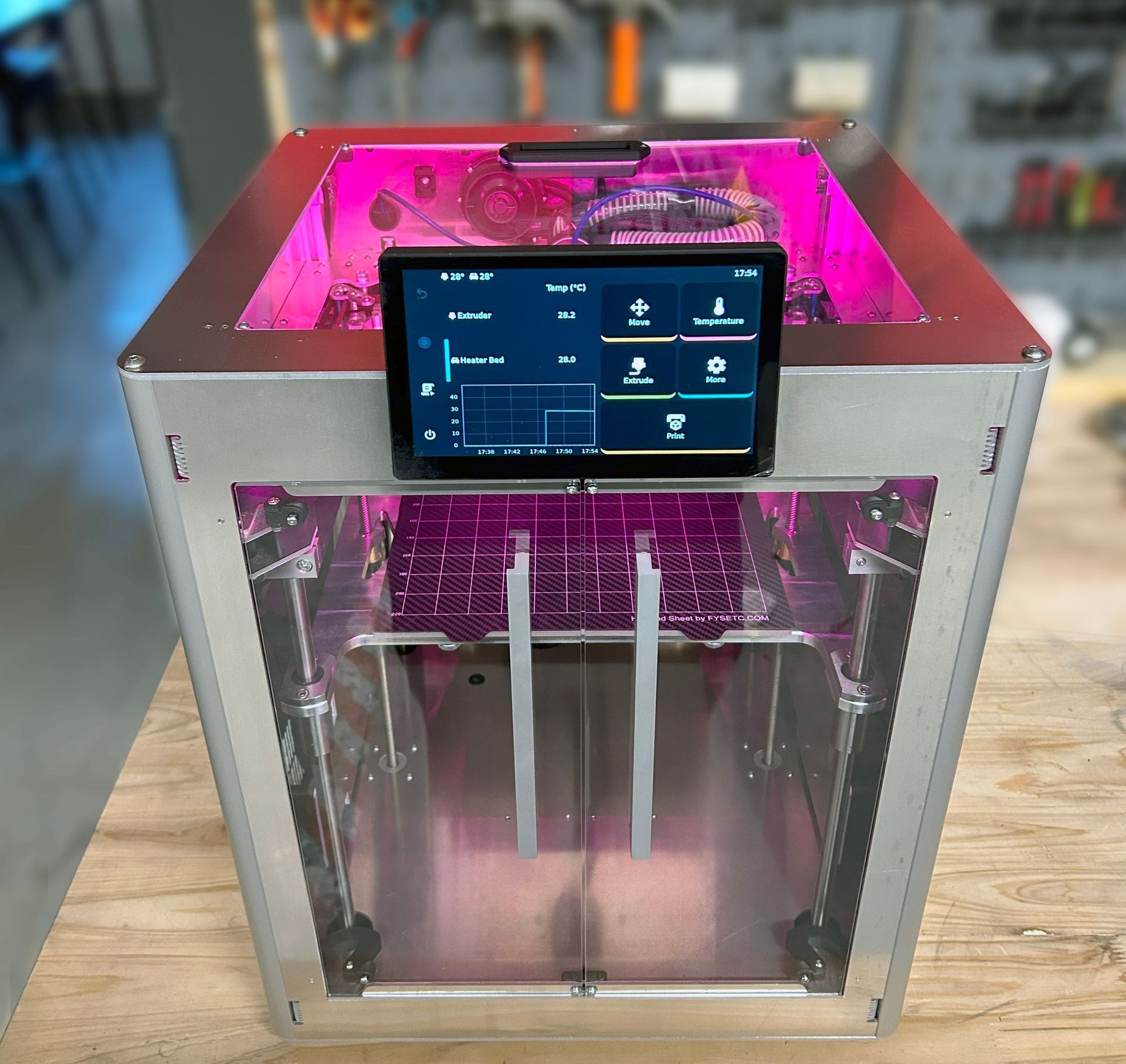

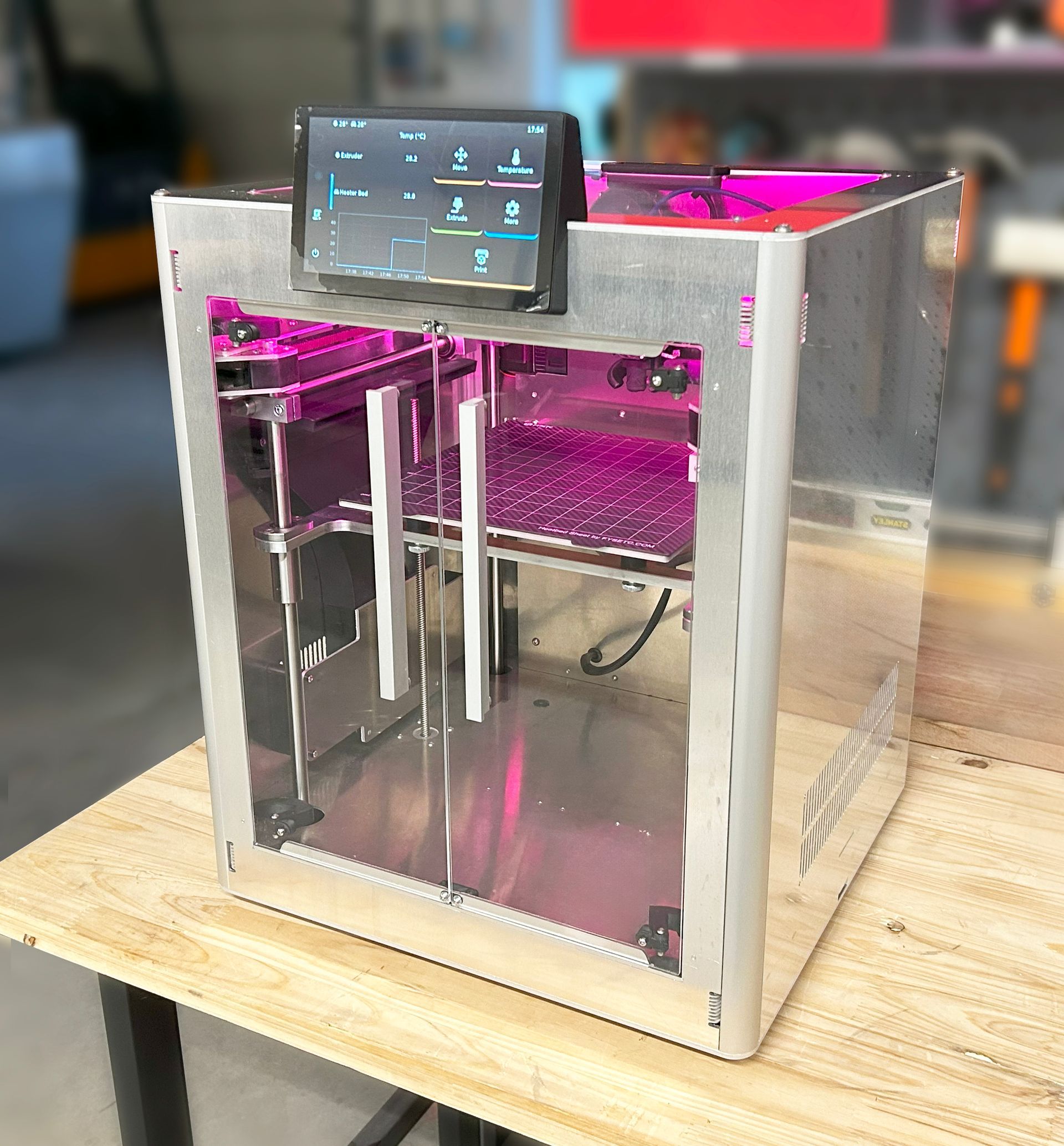

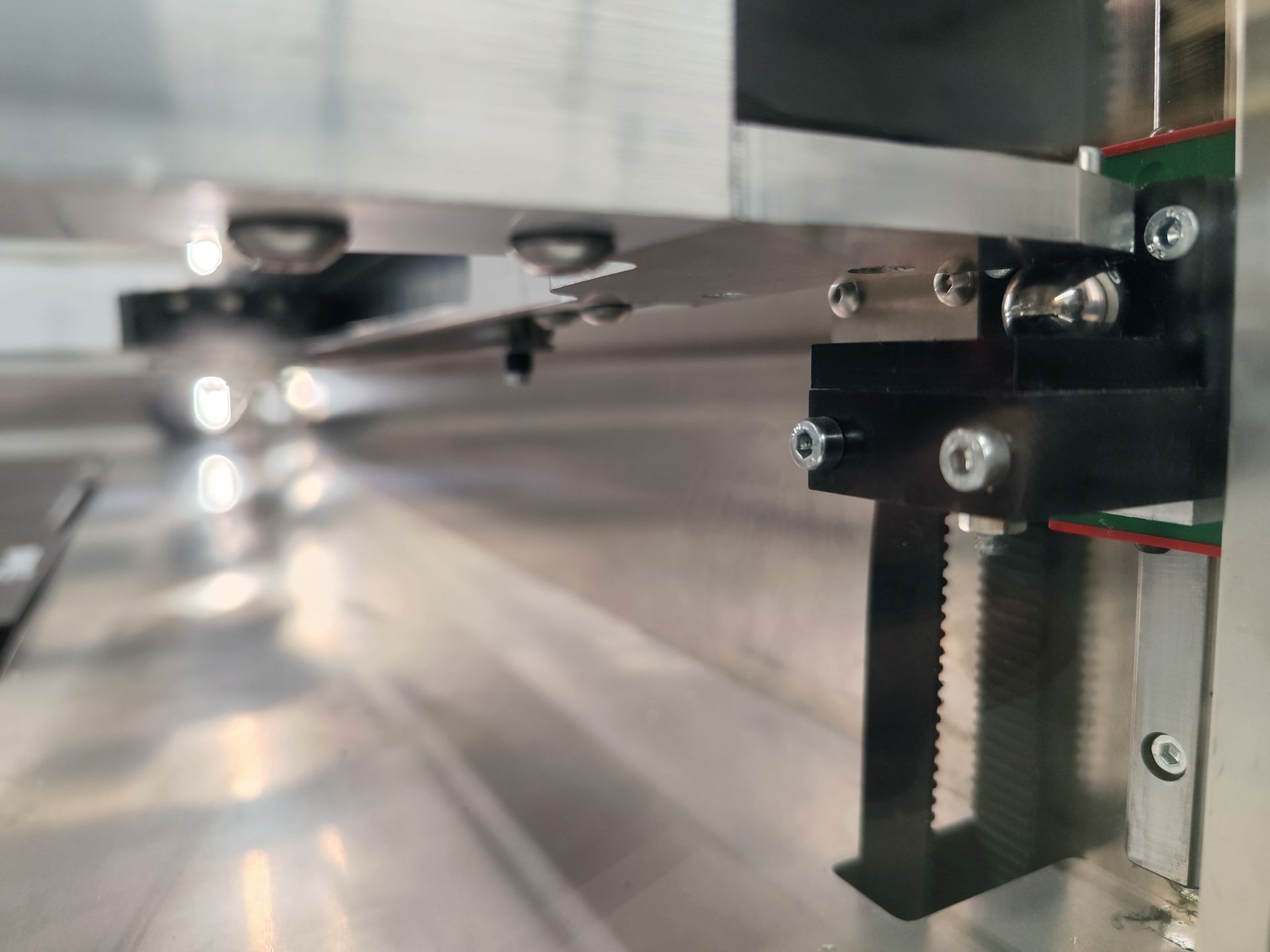

OLSK Small 3D Printer v3

OLSK Small 3D Printer v3 is an open-source desktop 3D printer with active cooled Core XY motion system and independent Z motors. The calibration automatically takes place before each print under 5 min with the Eddy Current Surface Scanner. It also features a built-in accelerometer, an enhanced cooling system with auxiliary part cooling fans, high flow nozzle and filament sensor. The housing is fully enclosed for thermal stability. To facilitate the maintenance, the magnetic beds are removable and the electronic compartment is easily accessible.

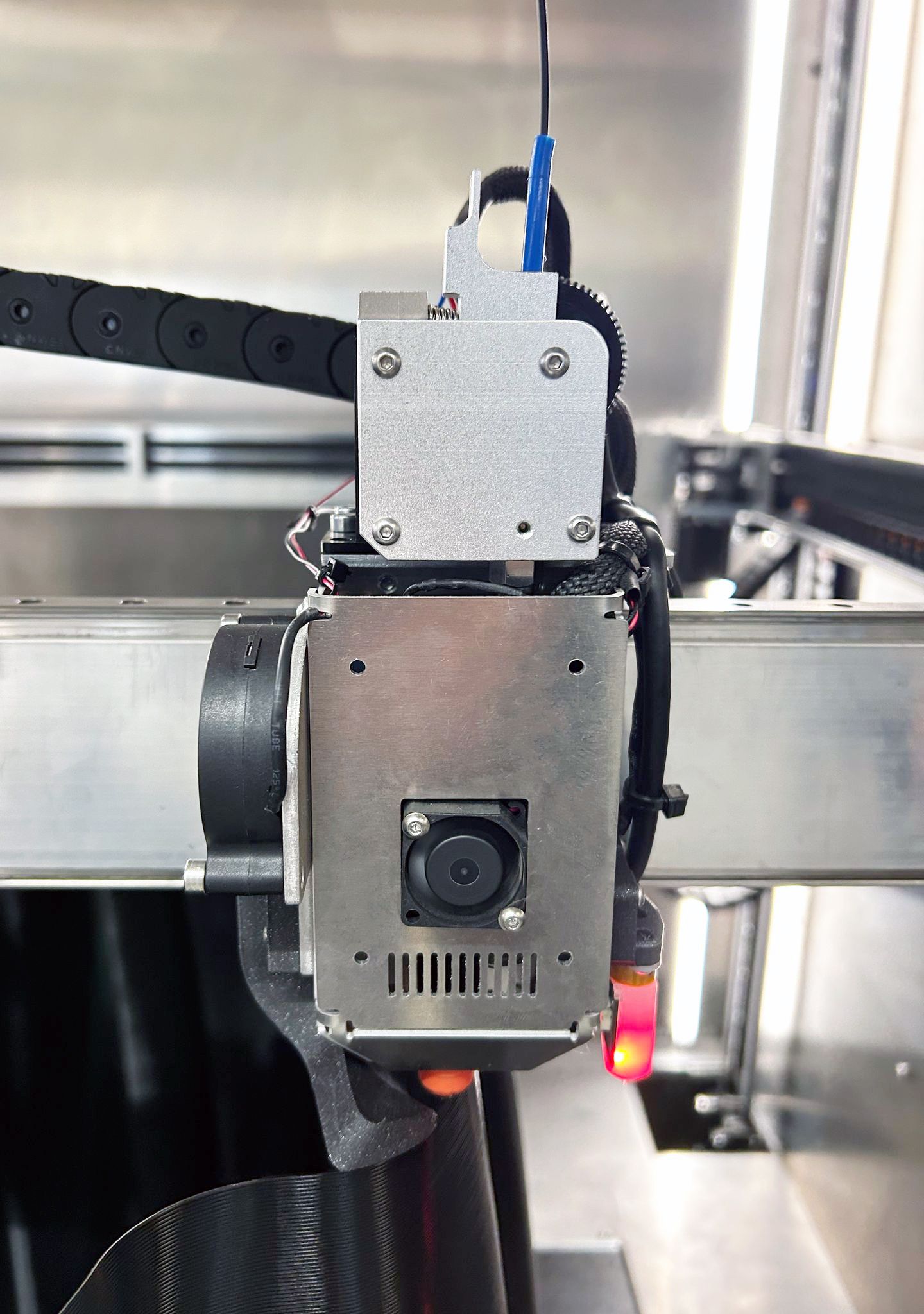

OLSK Large 3D Printer v3

Big format 3D Printer with printing volume of 1000 x 1000 x 1300 mm, making it the largest open source 3D printer. Its housing is fully enclosed, with access on two sides. The bed system features an efficent automated modular heating and Eddy Current Surface Scanner, with 1000 m/s travel speed. It has an industrial design, using linear rails on all axis, a quad-point self-leveling core XY gantry and a built-in accelerometer. The kinetic joints enable a non-planar printing. It also offers local and remote access, with customized Klipper firmware, touch screen, camera, LED status indicator, easy belt tensioning system and ethernet and WiFi connectivity.

OLSK Small Laser v2

This small format laser cutter features Fabulaser Mini design. Built with aluminum interlocked plates as frame, it has compact dimensions of 1161 x 812 x 390 mm but large cutting area of 600 x 400 mm and powerful 40W CO2 laser, which can cut up to 8mm acrylic and plywood. It was designed with redundant safety and quality industrial components.

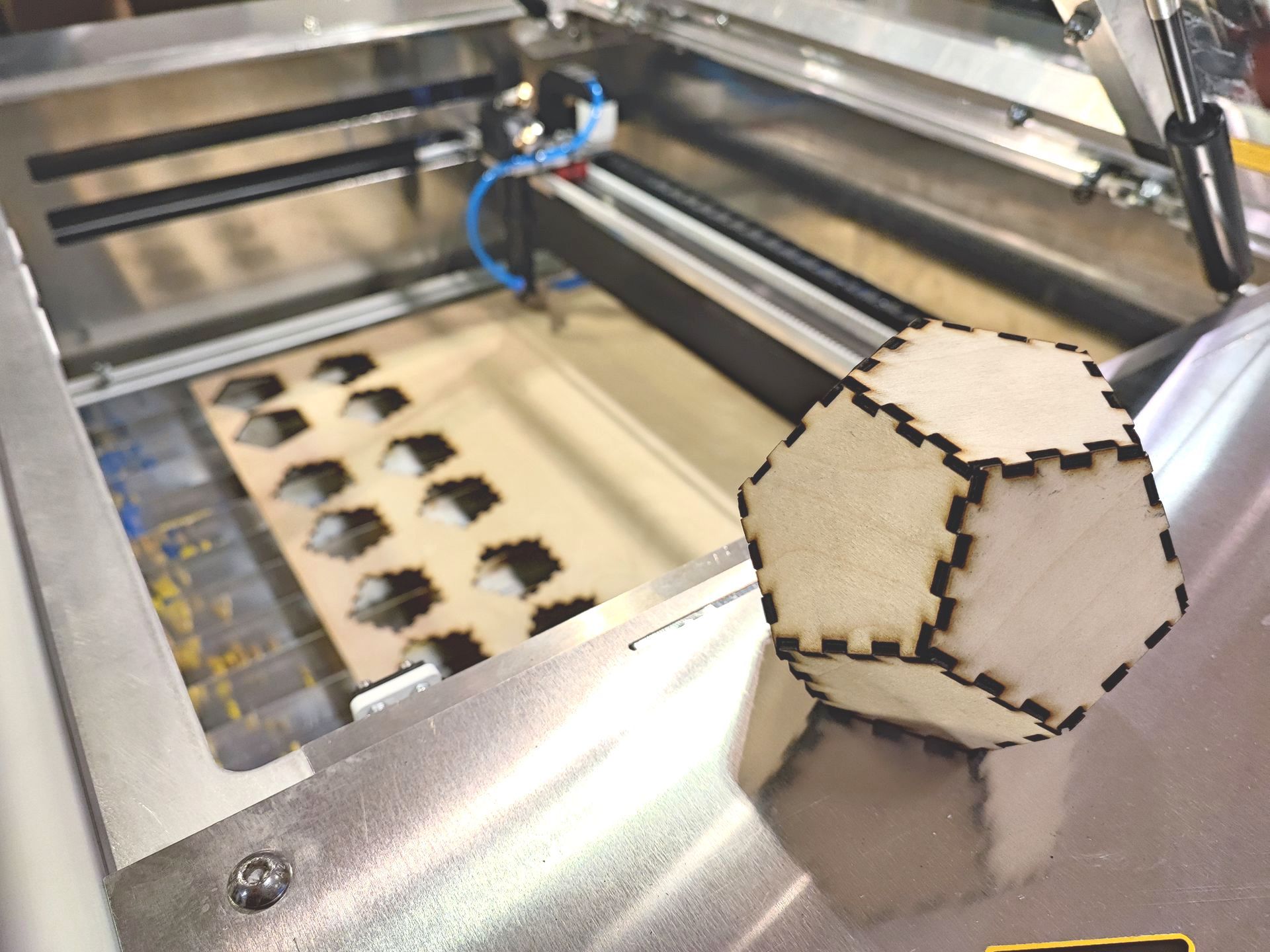

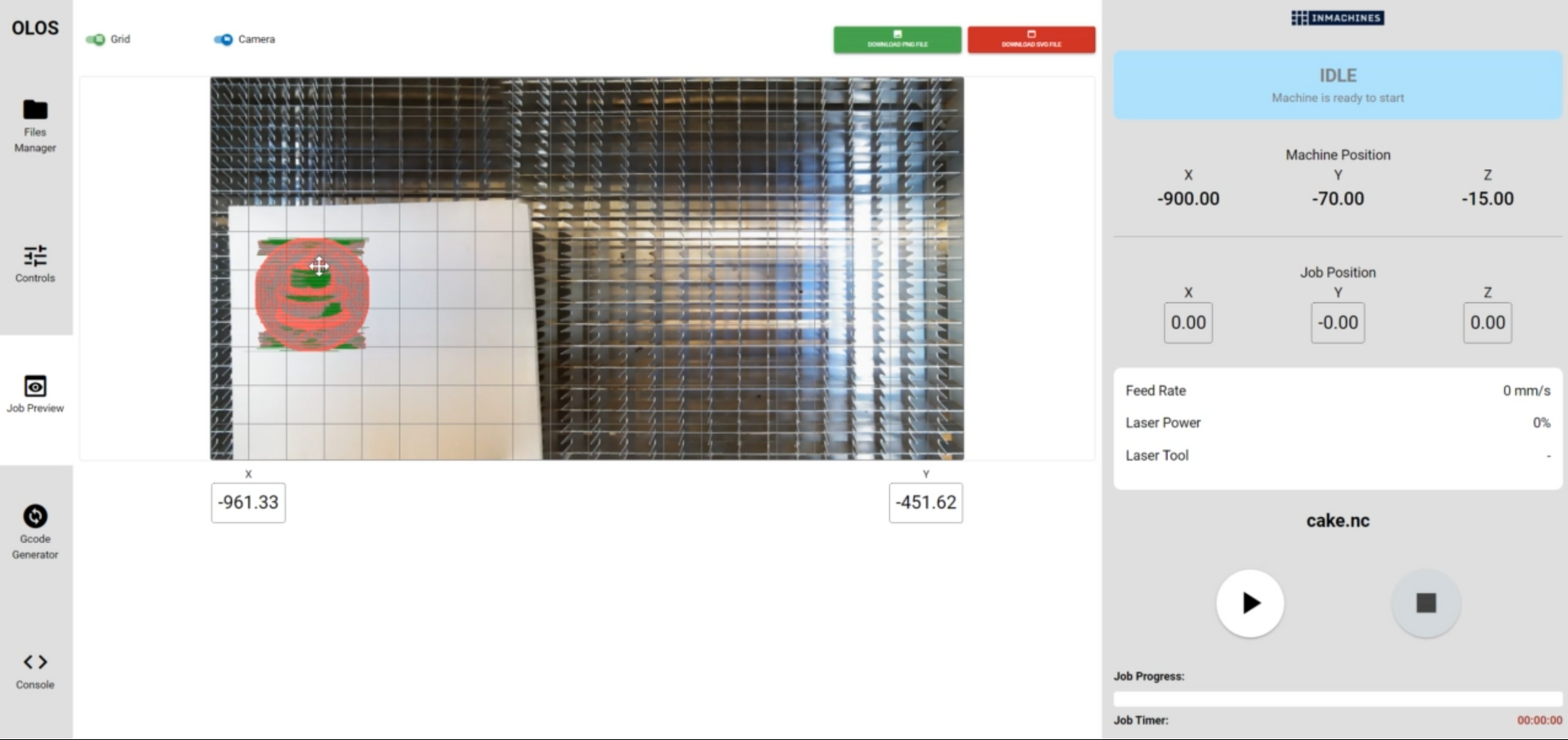

OLSK Large Laser v3

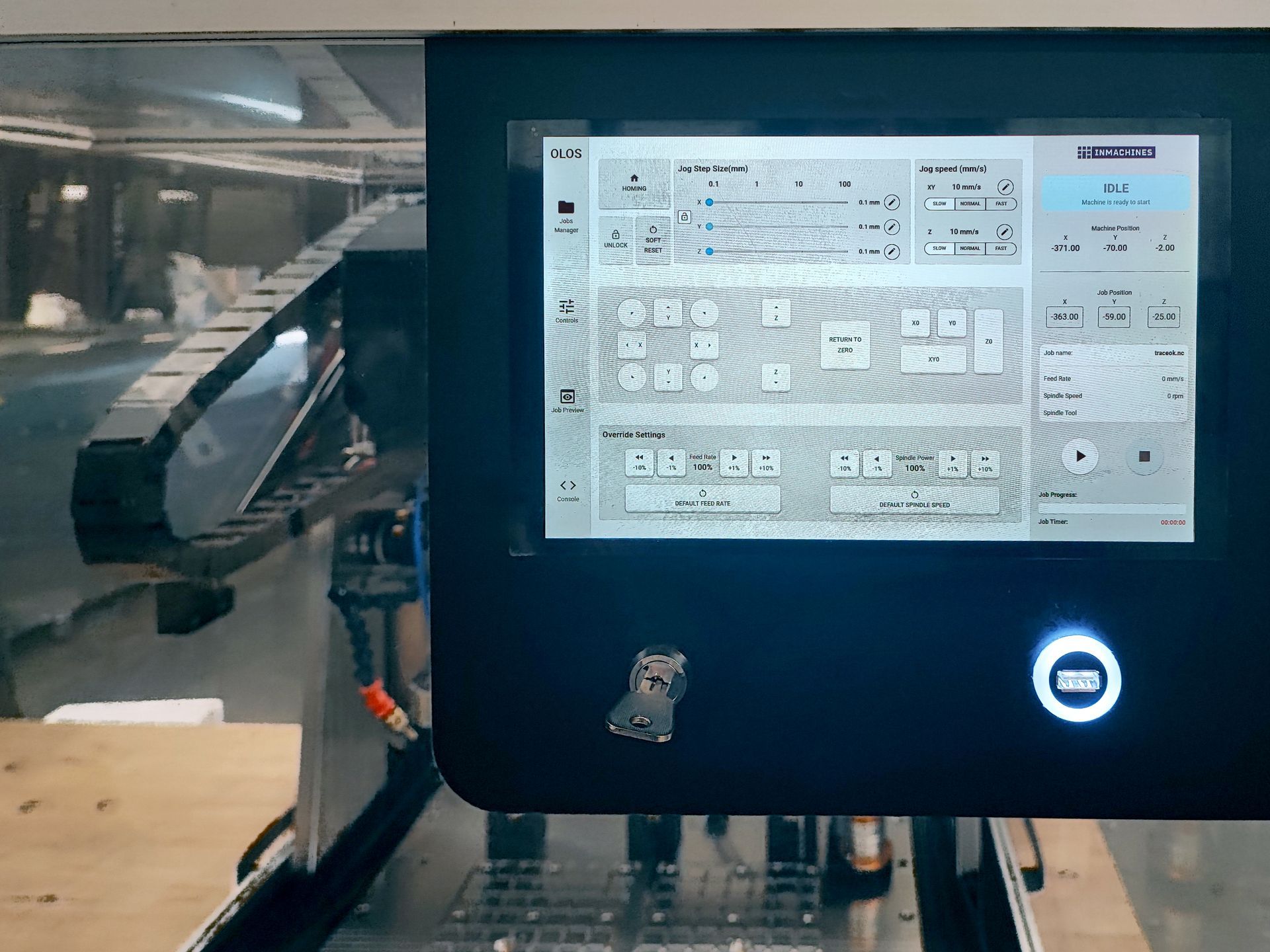

This innovative large format laser cutter is the first open source RF laser and the first laser cutter with a tool changer. Using magnectic knematic coupling tools, it supports multiple laser sources such as diode 40W, CO2 40W and CO2 60W, automatically changing the focal length and transfering the power. Its innovative chamfered design has a touch display mounted on the window, integrated light with status indication and dual 16 megapixel camera. The operation is controlled by OLOS, the in-house software, which allows several features such as Gcode generation, job preview, WiFi and ethernet connection, image positioning system and AI image generation.

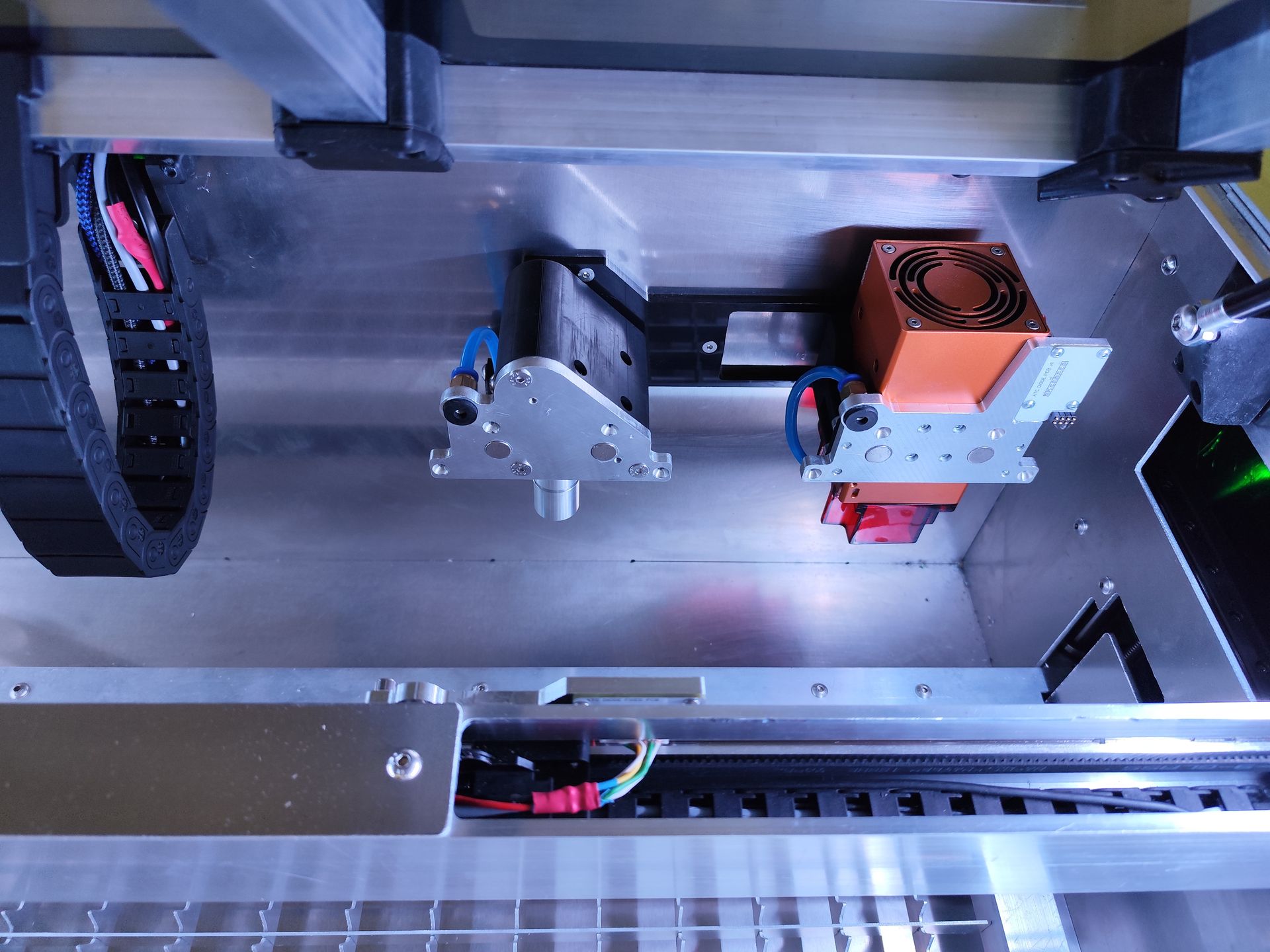

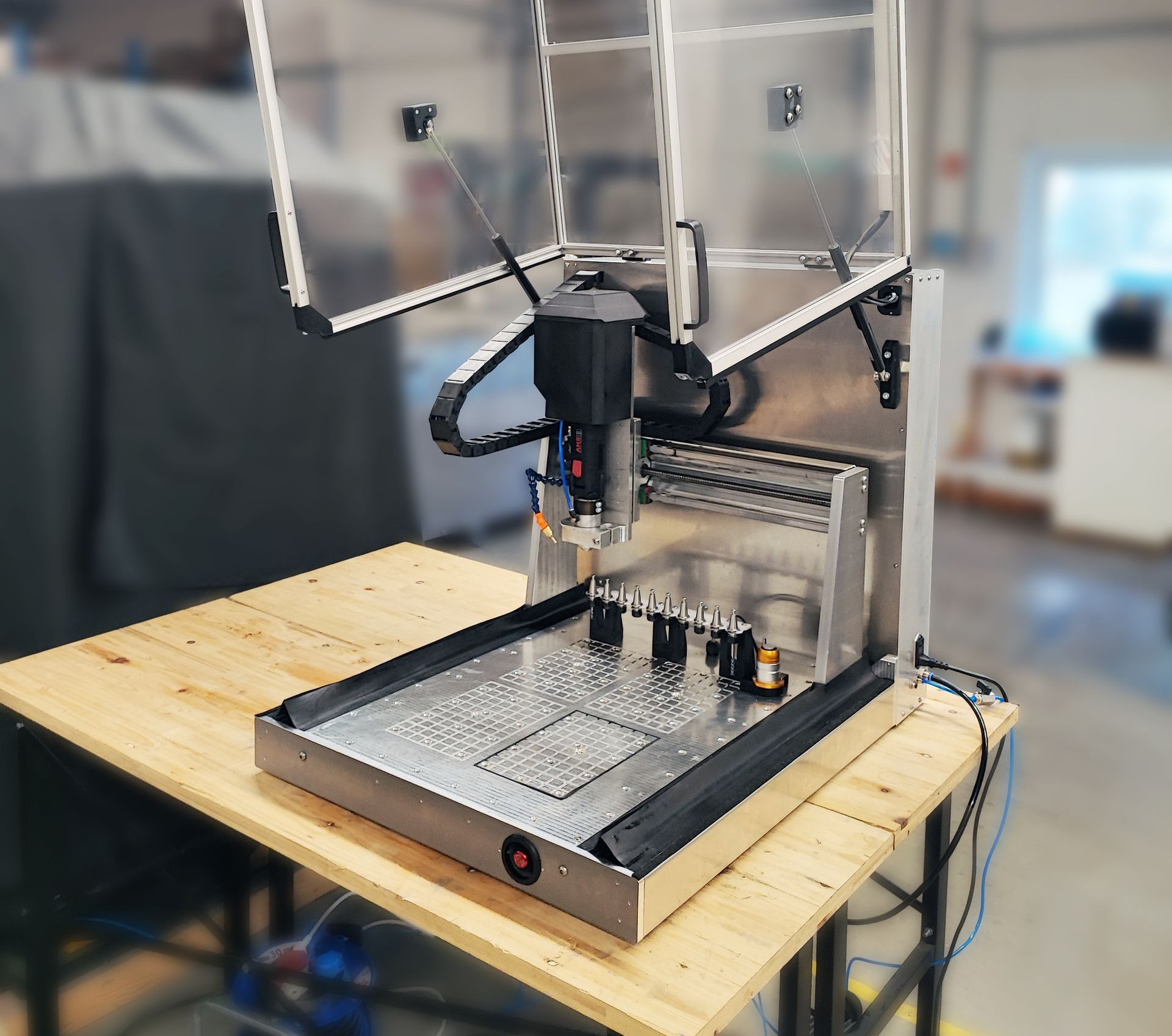

OLSK Small CNC v3

Desktop CNC milling machine with an innovative open-source tool changer, one of the first in an open-source machine. Its compact and sturdy design with aluminum frame has a milling volume of 400 x 600 x 150 mm (X x Y x Z). The tool changer, with capacity of 10 tools, conveniently offers tool measuring and cleaning. Safety features include a fully-enclosed housing with liftable window, flush-mounted 24V emergency stop and key lock. The milling machine also includes a coolant system, universal bed (fixture clamping and vacuum), mounted touch screen and OLOS system.

OLSK Large CNC v3

This open source large format CNC milling machine offers a milling area of 2500 x 1250 mm. With an industrial design, its structure is entirely made of standard beams and an integrated pneumatic system. It features an automatic tool changer with a capacity for 14 tools, tool sensor, tool cleaning, pneumatic coupling and 4.5 KW spindle. The housing is fully enclosed, with access on three sides through liftable windows, increasing its safety, in addition to the 24V emergency stop, the industrial electronic system with safe power setup with contactors, residual current device and circuit breakers. Operated with OLOS software, it also offers WiFi and Ethernet connectivity and mounted touch screen.

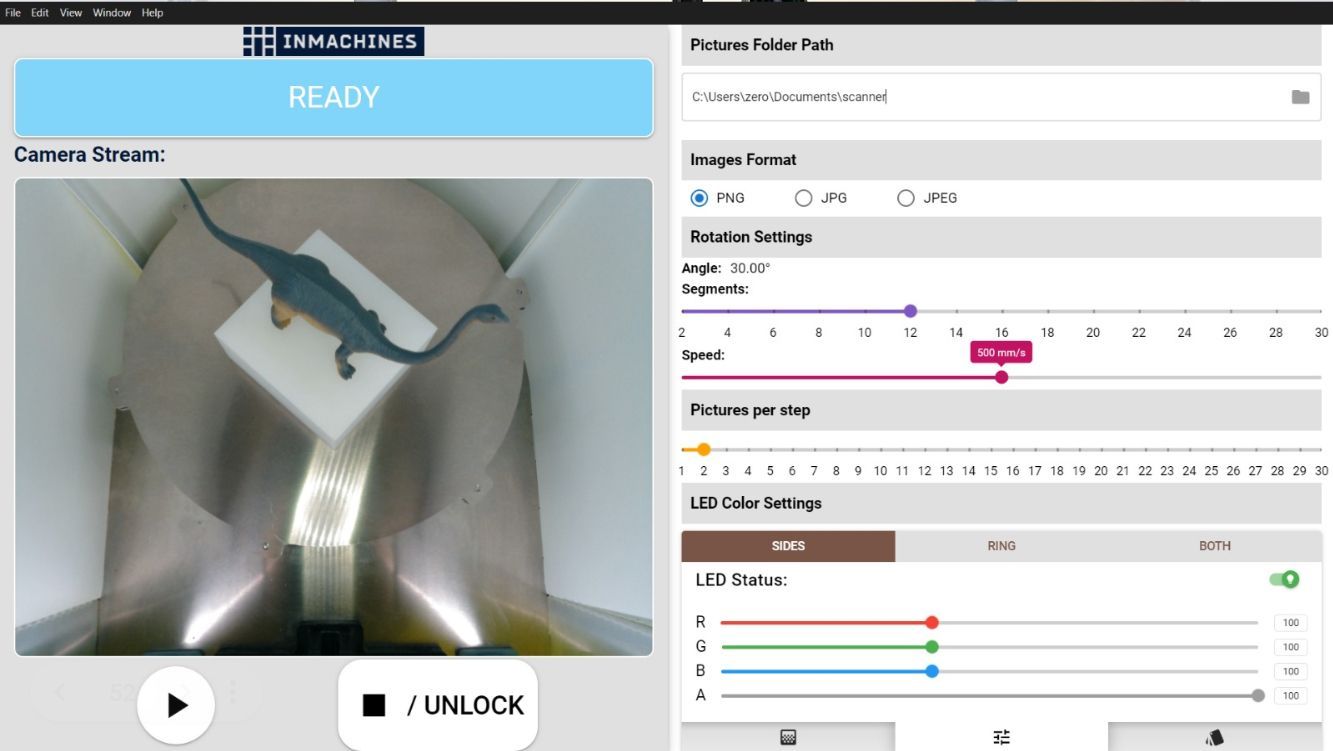

OLSK 3D Scanner v3

The OLSK 3D Scanner is an open-source 3D scanner with a combination of one moving camera and a rotating turntable. It features a fully enclosed environment, 2x adjustable LED lights and adjustable number of pictures per rotation and per arc travel for a better caption of the model. With a very simple and compact design, this machine can be easily replicable and assembled in Fab Labs, schools or at home.

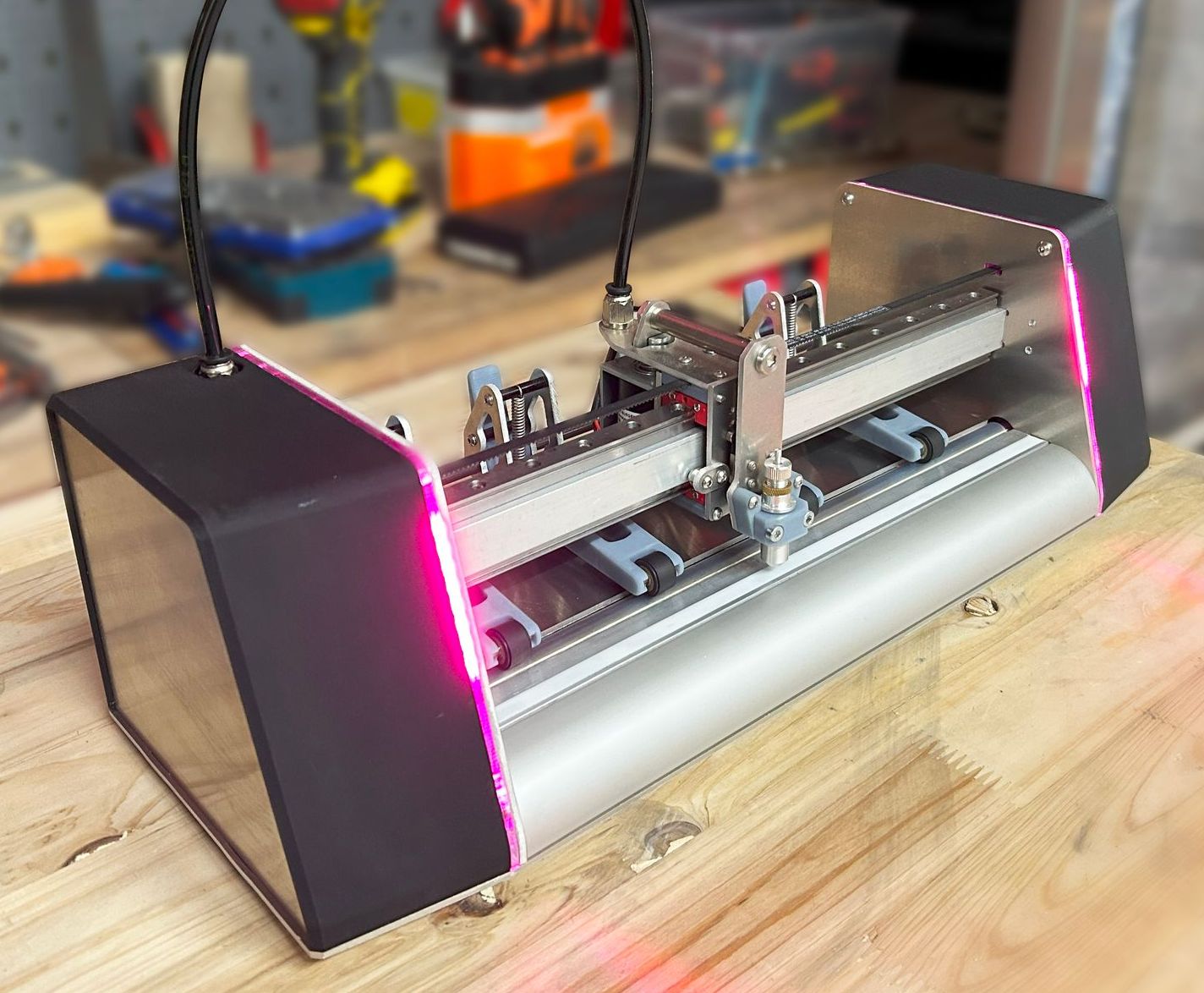

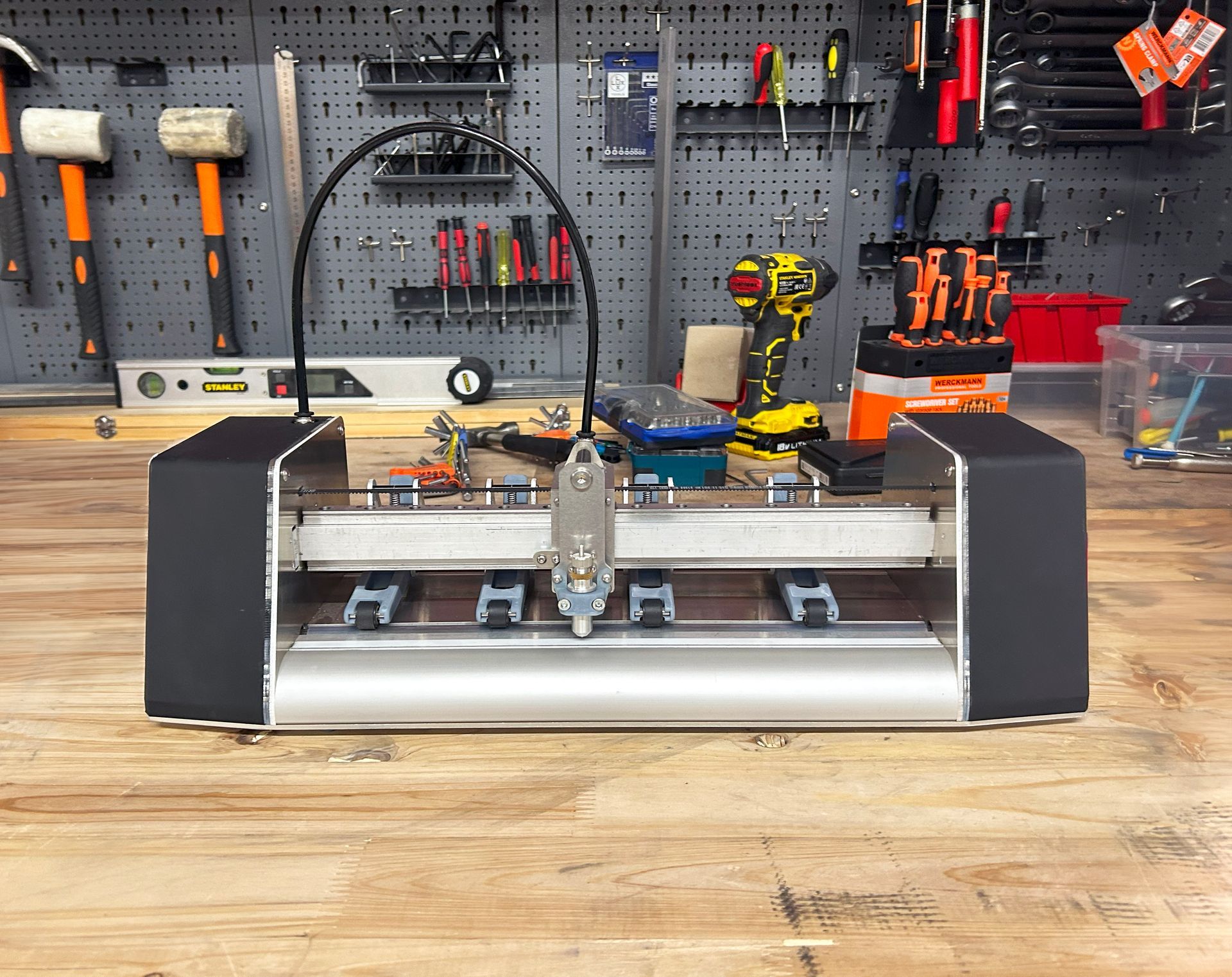

OLSK Vinyl Cutter v3

The OLSK Vinyl Cutter is the first open source vinyl cutter available. With a compact footprint and robust stable construction, it offers a cutting width of 297 mm (A3 size). The TMC drivers with 1/256 microstepping interpolation allows a smooth and quality cut. It also includes 4 pinch rollers with bistable locking mechanism and a manually regulated knife, which can be exchanged for other tools such as a drawing pen. Operated with OLOS, featuring job preview and file management.